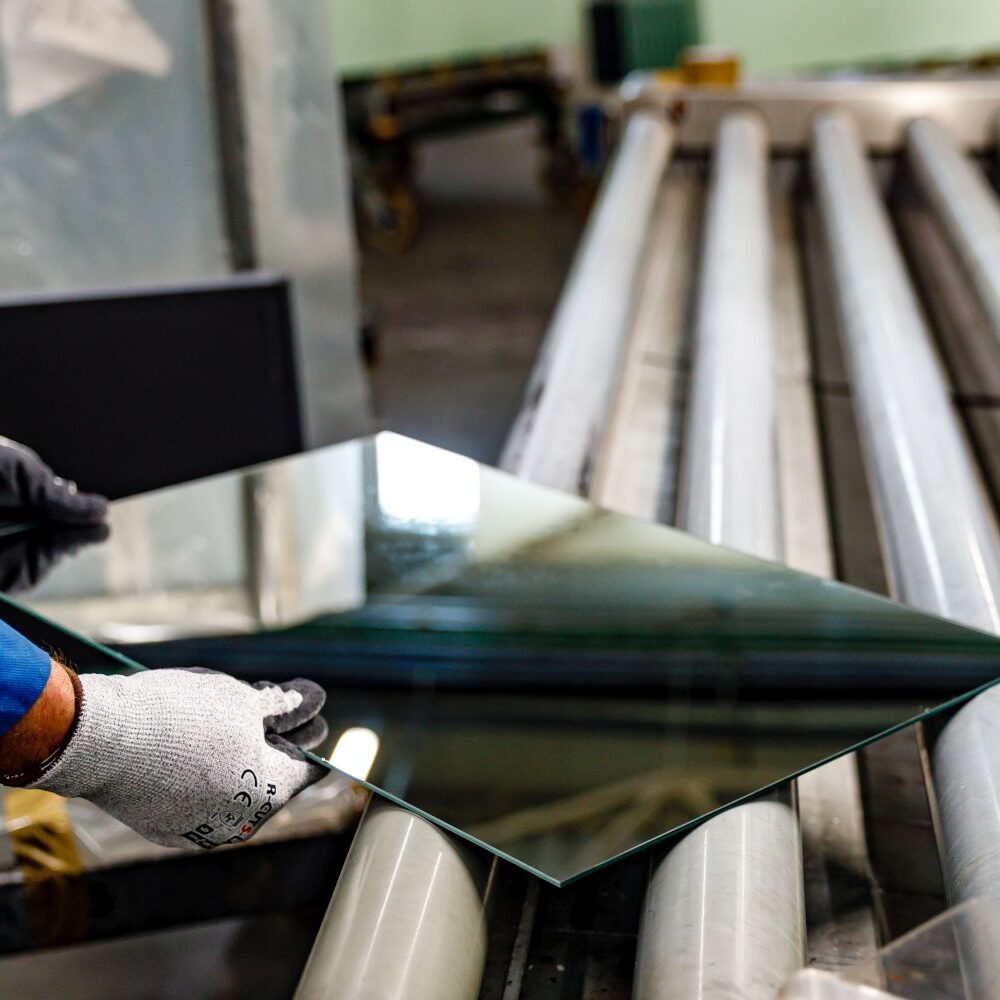

Glass grinding

After the glass cutting process is carried out, the edges of the form remain sharp and irregular. The operation which eliminates these features and allows to obtain a carefully processed edge of the glass pane is the grinding process. Only precisely ground glass meets the functional requirements and is suitable for possible further processing.Grinding, in addition to the aforementioned utility values, performs one more, very important function – it increases the safety of glass use. Before the grinding process is carried out, the edges of the glass are rough, sharp and full of micro-cracks. The grinding process not only levels and smoothes any unevenness on the edges of the glass, but also contributes to reducing the risk of glass breakage caused by mechanical or thermal stresses on the surface of the glass.

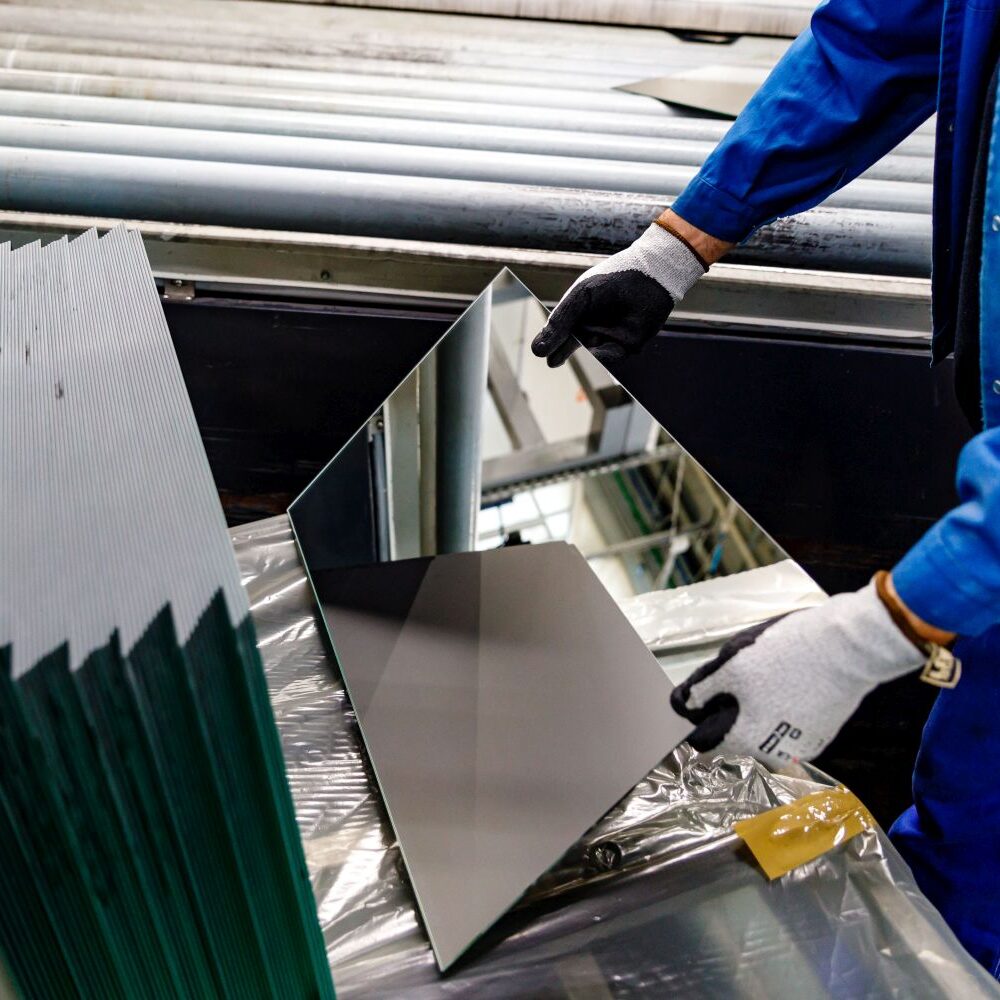

Glass grinding is mainly used in relation to glass used in the production of furniture and glass shelves, frameless doors or shower cubicles.

An additional activity performed at the customer’s request is polishing the previously sanded edges of the glass. This treatment is carried out mainly due to the aesthetic value of the glass.

- glass dimension (max.): 2600×1600 mm

- glass thickness: 3 – 12 mm

- griding type: polished, matte

- cut type: C-edge, F-edge